Product Features

This machine adopts the servo compensation system and motion control system, optimized design, use of multiplesets of photoelectric sensor at bottom paper relative position, control top paper on both sides of the servo motor totracking speed, independently compensation , so that accurate positioning of top paper and the bottom paper.Weuphold the "people oriented" design concept, simple operation,just input the paper size, machine can automaticallyfinish adjustment.

Servo Control Compensation Positioning . One-Key Commission

Max Speed 12000 Sheet/Hour

Fully lntelligent Automation

Composition & Module

Feeder System

Equipped with high speed dedicated feeder offour-sucking and four-feeding, both paperlifting and feeding nozzle can adjust angle tothe paper, to ensure that whether paper istilted left or right can be delivered rapidly andsmoothly.

Bottom Paper Feeding System

Use servo motor control system, adjustablesuction power, to ensure corrugated paperand cardboard goes out smoothly and simpleoperation.

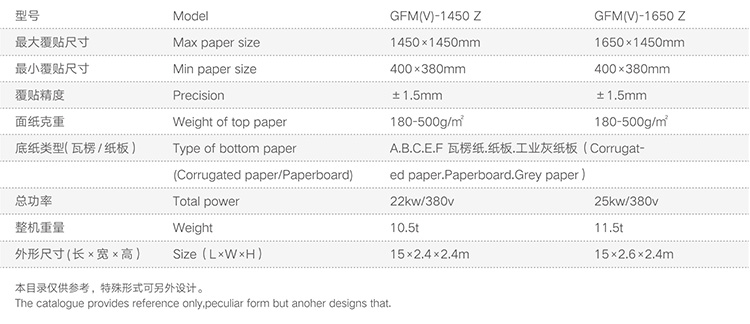

Top Paper Feeding System

Two top paper feeding modes,single paperfeeding and overlap paper feeding for choice.

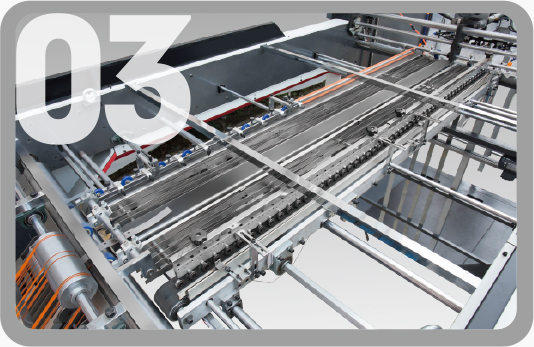

Mainframe wall System

4cm casting wallboard, not easy to deformation,stable movement.

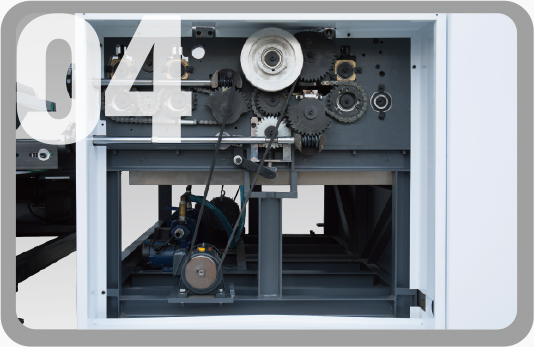

Glue Roller

The special design of roller, after narrowlygrinding, guaranteed the glue coated evenly.Down roller be cleaned by water roller.

Positioning System

Use multiple sets of photoelectric sensor atbottom paper relative position, control toppaper on both sides of the servo motor to doindependent compensation action, so thataccurate positioning of top paper and thebottom paper.

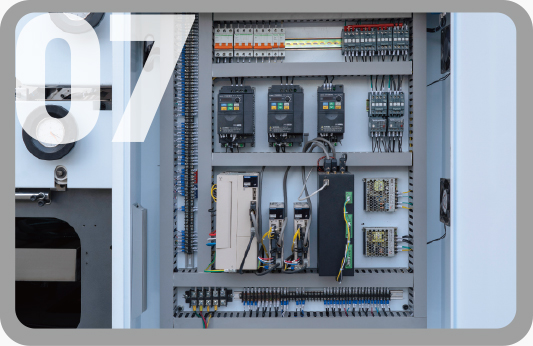

Electrical System

Use man-machine interface and PLC combination, display all the information, suchas parameter setting, operating speed, faultdetection and warning, etc on the screen .That ensure the machine stability and efficiency.

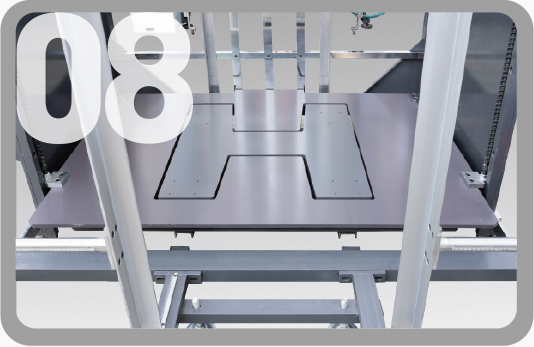

Pre-stack Part

Pre-stack pile of paper under the condition ofnon-stop, improve efficiency.The specialdesign of pre-stack paper frame, convenientand efficient.

Mobile Site