GFM-1300/1450 H high-position automatic laminating machine (single station) performance characteristics:

GFM series improved single-station laminating machine is the essence of our company's combination of many card and tile laminating machines. It integrates light, electricity, machine and gas.

A perfect combination of one, adhering to the "people-oriented" design concept, a new-generation high-precision laminating machine developed on the basis of the original single-station laminating machine.

1. Unique front gauge design, with intelligent control, to ensure accurate fitting and positioning;

2. The good pneumatic design reduces the labor intensity of workers, saves adjustment and cleaning time, and greatly improves work efficiency;

3. Electrical control department: The whole machine adopts frequency conversion speed regulation, PLC centralized control, precise operation control, real-time monitoring of glue level, water level, and bonding gap, realizing man-machine dialogue;

4. Facial paper conveying section: The facial paper adopts the humanized design of manual frontal advancement, and the height of the feeding table is 1.85 meters, making it easier and more efficient to add backing paper;

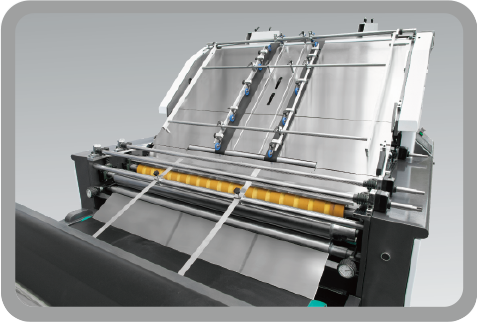

5. Bottom paper conveying section: The large-sized suction system provides strong suction, and through a number of perforated suction belts, the bottom paper is tightly sucked to ensure smooth and accurate output of the bottom paper during high-speed operation;

6. Gluing and bonding department: automatic glue replenishment system, and can timely detect the amount of glue in the glue container to avoid glueless bonding; the special mesh design on the coating roller, the glue is evenly applied, which can save glue consumption and solve the problem of coating and scraping;

7. Cleaning department: The dip-coating cleaning system ensures that the back of the backing paper is clean, and the double scraper cleaning does not need to be replaced frequently. Compared with circulating water cleaning, the workplace is clean, and the circulating water blocks the pipeline and overflows the ground;

8. Gap adjustment part: The main roller gap is adjusted by a digital position display, which can record data, and is more efficient and safer when changing paper types;

9. Bottom paper baffle adjustment part: The integral structure ensures that the baffle can be adjusted easily and flexibly from left to right; the baffle will not be stuck or inclined.

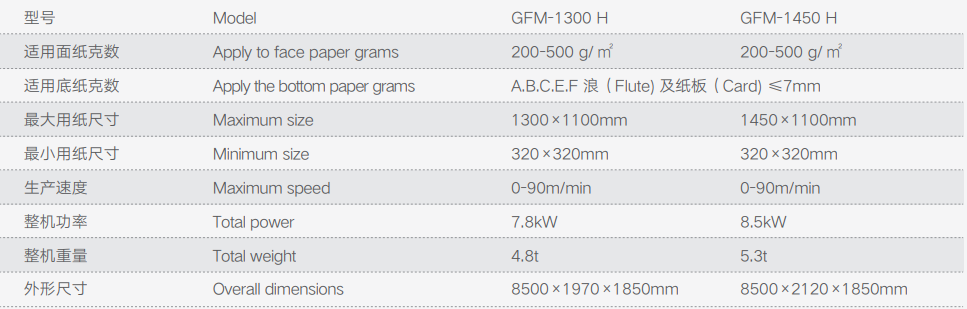

Laminating machine technical parameters:

The module of the laminating machine:

touch screen, servo system

All stainless steel panel, sprayed appearance

Digital Display Adjustment Gap

Automatic glue replenishment, anilox roller gluing

Centralized lubrication oil supply

Grid strong bottom paper suction

Paper feed pedal

Facial paper electric lift truck (optional)

>

Mobile Site